3D Printing Innovations in Cricket Equipment Design

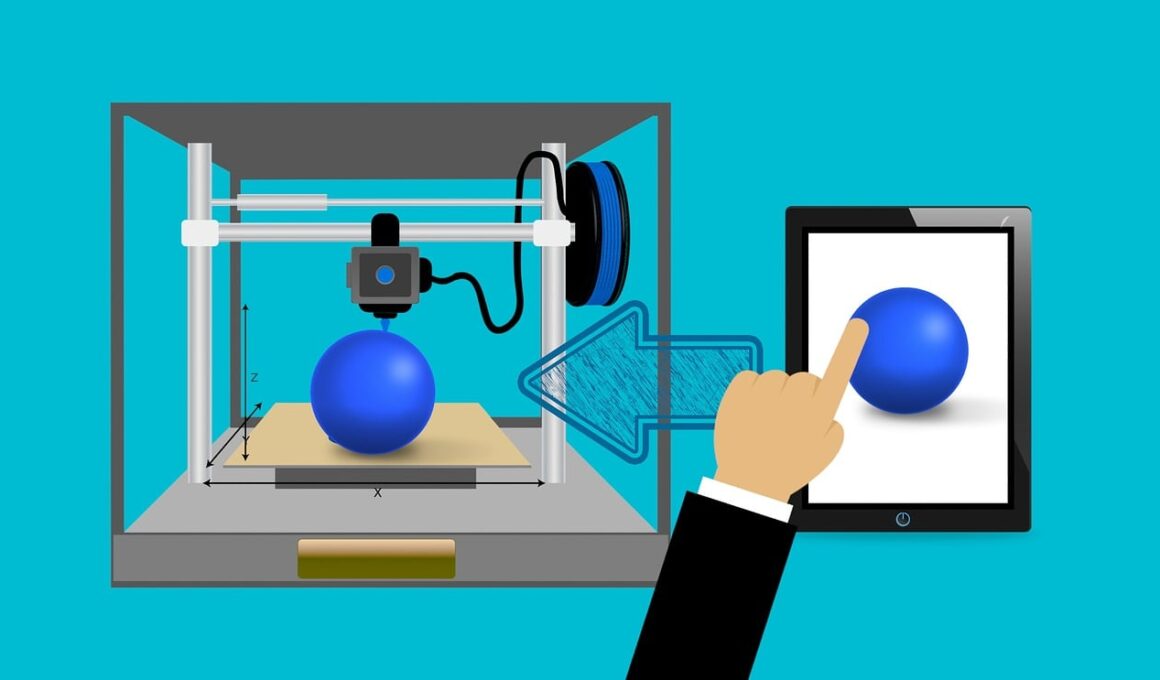

In recent years, 3D printing technology has made significant advancements, transforming various industries, including sports. Cricket has seen innovative designs emerging through 3D printing, which enhances performance and customization. One of the most vital pieces of equipment, the cricket bat, can now be tailored to a player’s specifications. Players can personalize weight distribution, grip size, and shape—all controlled through digital designs. This level of customization helps players perform better, as every stroke and shot becomes optimized for their unique batting style. Moreover, the materials used in 3D printing, such as thermoplastics and resin composites, are lightweight yet durable, ensuring longevity while maintaining performance standards. Brands are investing heavily in this technology, introducing prototypes that promise to redefine the standards of product quality. Continuous material refinement results in bats that are increasingly fine-tuned for performance. The integration of this technology provides new opportunities for cricketers, enhancing their training and overall gameplay experience. This article explores the impact of 3D printing innovations on cricket equipment, particularly focusing on bats, pads, and helmets and discusses the potential for future developments within the sport.

As cricket evolves, so does the technology that supports it. The impact of 3D printing isn’t limited to bats alone; it extends to other essential gear like pads and helmets. Manufacturers are now capable of 3D printing cricket pads that perfectly conform to a player’s legs, enhancing comfort and protection. Traditional manufacturing methods often involve compromises in fit, but 3D printing allows for bespoke designs that cater to individual preferences. Additionally, helmets can now be customized not only for fit and comfort but also for enhanced safety features. By using advanced materials, manufacturers can produce helmets that offer better impact resistance without increasing weight, maintaining balance during play. One exciting aspect is the ability to conduct rapid prototyping, allowing for quick iterations of designs and materials. This means player feedback can be implemented much faster than before, leading to continuous improvements in gear quality. As a result, cricket players are likely to experience equipment that is not only better suited to their needs but also more efficient at providing protection, ensuring that 3D printing could change cricket’s landscape dramatically moving forward.

Research and Development in 3D Printed Cricket Equipment

The research involved in developing 3D printed cricket equipment is crucial for realizing the full potential of the technology. Important aspects such as the physics of materials, player ergonomics, and safety standards are routinely analyzed to create optimized designs. Collaborations between manufacturers and sports scientists are becoming increasingly common, leading to thoughtful approaches towards equipment innovation. Through experimental studies, manufacturers can assess how different designs and materials perform under varying conditions. This is particularly critical for cricket, where various elements, including weather, field conditions, and player styles, come into play. The use of computer-aided design (CAD) software allows engineers to simulate performance aspects efficiently. This results in wasted materials and time being minimized, as only designs likely to succeed are produced. Furthermore, feedback from professional players is invaluable, as users can provide insights that lead to better functionality. Ultimately, understanding the nuances of both technological advancement and player experience is pivotal. As technologies grow increasingly sophisticated, further enhancements in cricket gear are expected, paving the way for improved player safety, comfort, and performance.

One of the most significant advantages of 3D printing in cricket design is the streamlined production process. Traditional manufacturing methods require molds and extensive setups, which can be costly and time-consuming. In contrast, 3D printing allows for rapid production of equipment without the need for molds. This means that prototypes can be created quickly and tested, leading to faster iterations and improvements. In addition to speed, 3D printing also offers manufacturers the ability to produce low-volume, highly customized items at a cost-effective price. Hence, smaller brands or startups can enter the market with innovative designs that could potentially disrupt established players. Another exciting development is the accessibility this technology offers to amateur players. With 3D printing becoming more affordable and accessible, young cricketers can get custom gear tailored to their needs, which was once available only to professional athletes. Amateur players now have the opportunity to experience the same benefits of custom-fit equipment as professionals do. Consequently, this creates a more level playing field, allowing aspiring players to develop their skills with equipment designed specifically for them.

Future Trends and Possibilities

Looking ahead, the future trends in cricket equipment design through 3D printing appear promising. Manufacturers are exploring the use of smart materials that may further enhance player performance. These materials include sensors incorporated into the equipment to monitor metrics such as speed, power, and technique during practice or matches. The data collected can help players fine-tune their skills, thereby optimizing their performance on the field. Moreover, sustainable practices are likely to become more prevalent in 3D printing, with an emphasis on recycling and using eco-friendly materials. This aligns with the growing emphasis on sustainability in sports, encouraging manufacturers to adopt more responsible practices. Furthermore, we might see an increase in collaboration between technology companies and cricket equipment manufacturers. Such partnerships could lead to radical advancements, ultimately shaping the landscape of cricket significantly. As technological innovations continue to evolve, the landscape of cricket will adapt, providing players and enthusiasts experiences never before imagined. Hence, the future of cricket equipment design is both exciting and unpredictable, paving the way for a new era in the sport.

In conclusion, the integration of 3D printing innovations into cricket equipment design is just beginning to show its significance. As more manufacturers embrace this technology, it brings forth not only customized solutions but also advanced safety and performance features that directly benefit players. The ability to create equipment that caters to individual needs marks a pivotal shift in the way cricket gear is designed and manufactured. With ongoing R&D efforts, the cricket community can expect an abundance of superior gear available in the near future. Additionally, the rise of grassroots cricketers gaining access to tailored equipment allows for a more inclusive environment within the sport. Furthermore, as sustainability becomes an increasingly urgent consideration, the transition to eco-friendly materials and practices can be anticipated. This shift not only enhances player performance but also aligns with the values of modern sports culture. Future developments could set new benchmarks for equipment standards, enhancing not only the game’s integrity but also player enjoyment. As the cricket industry pivots towards more innovative technologies, enthusiasts are excited about what the future holds in cricket equipment design.

The Impact on Player Performance

Finally, one cannot overlook the impact that 3D printed equipment will have on player performance. Customization allows players to truly develop their unique playing styles, catering to their specific needs during training and matches. As bats become more tailored and protective gear improves, players can focus on technique rather than equipment deficiencies. Enhanced performance translates into better results on the field, making the game exciting for both players and fans alike. Additionally, as new technologies emerge, the learning curve for new players may lessen with gear designed to facilitate performance improvement. Novice players equipped with well-designed gear can enjoy a more streamlined learning experience, thus enhancing their skills more quickly. Youth cricket programs can also incorporate 3D printed equipment into their training regimens, instilling good techniques from a young age. This holistic approach not only benefits individual players but strengthens the entire sport over time. As cricket keeps evolving, the embrace of technological advancements will consistently border on sustainability, performance, and preference. Therein lies the future challenges and opportunities that cricket and its stakeholders will continue to tackle.

The possibilities with 3D printing in cricket are vast and exciting, offering avenues for creativity and innovation. As players and manufacturers continue to collaborate, we may witness breakthroughs that redefine current standards. The realms of virtual reality and augmented reality might intersect with equipment design, providing players immersive training experiences. Manufacturers may develop platforms where players visualize their custom gear in a virtual environment, leading to informed decision-making regarding equipment selection. As the sport evolves, the potential for integrating technology within cricket is poised to resemble those in other segments of society. Furthermore, as cricket audiences grow more engaged, there are potential applications for fan involvement in equipment design. Crowdsourcing ideas for custom bats or the like could reveal new trends in preferred styles and features. Ultimately, the journey towards advanced cricket equipment design embodies a convergence of technology, art, and sport. The dialogue among stakeholders—including players, designers, and fans—will shape the future of cricket gear. With innovation at its forefront, cricket will continue to thrive in modernity, preserving tradition while paving the way for a brilliant future that awaits.