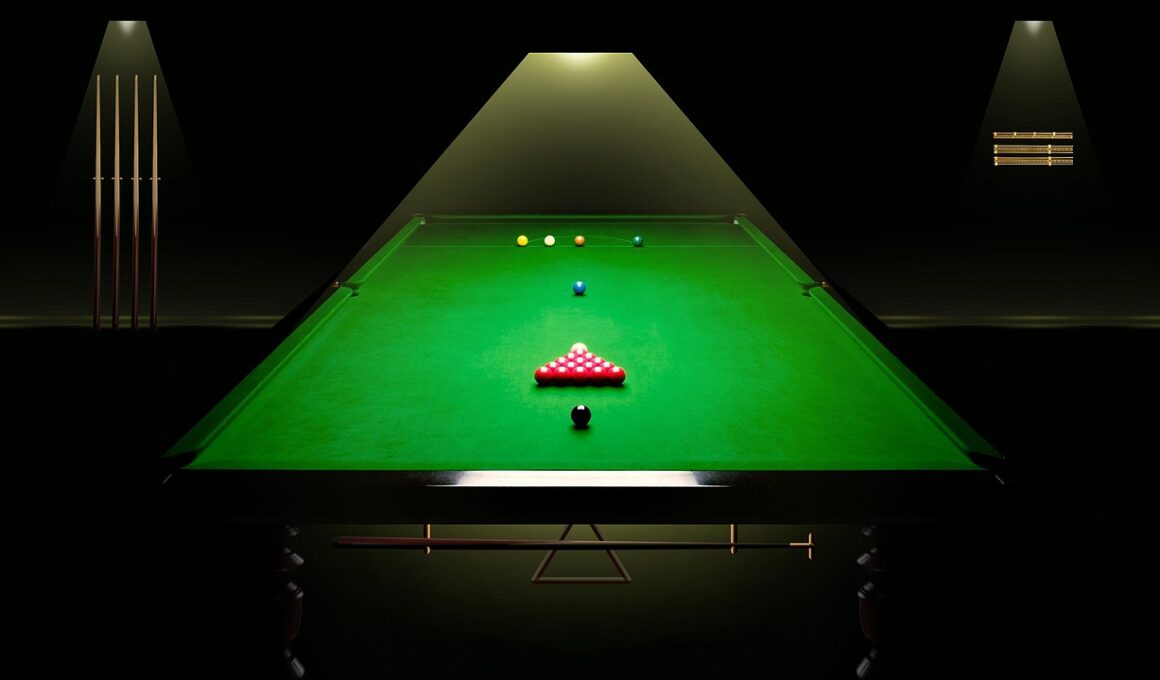

Materials Used in Manufacturing Snooker Balls

Snooker balls are primarily made from a combination of materials designed to enhance their performance and longevity. The traditional material for snooker balls is phenolic resin, which is a type of thermosetting plastic. This material is favored for its durability and resistance to wear, making it ideal for the constant impact and friction encountered during play. In addition to phenolic resin, manufacturers may also use various fillers and dyes to achieve the desired weight, balance, and color of the balls. The consistency in density and composition contributes to a uniform response upon striking the balls, which is critical for fair play. Furthermore, modern advancements have led to the exploration of alternative materials, including polymers and composite materials, which can offer different playing characteristics. Despite the innovation in materials, phenolic resin remains the industry standard due to its superior performance. The craftsmanship involved in molding and finishing these materials also plays a significant role in the overall quality of the snooker balls, affecting their feel and playability on the table. Ultimately, the choice of materials reflects the ongoing search for balance between traditional quality and modern performance.

The manufacturing process for snooker balls entails several intricate steps, beginning with the initial selection of materials. Once the phenolic resin is chosen, it undergoes an extensive molding process to form the individual balls. The resin is heated and placed into molds, where it is pressed to create the characteristic spherical shape of snooker balls. After this molding process, the balls undergo cooling and curing, which allows the resin to harden and solidify, ensuring they maintain their shape during gameplay. Once cured, the balls are polished to achieve a smooth finish, which is not only aesthetically pleasing but also improves their interaction with the snooker table. Following polishing, the balls are then subject to rigorous quality control measures. This often includes testing for weight, bounce, and visual defects. Quality control is paramount, as any imperfections in the surface or weight distribution can affect gameplay dramatically. The final stage of production involves the application of color and branding, allowing for personalization while ensuring adherence to the required specifications and regulations established by snooker governing bodies.

Impact of Material Quality

The quality of materials used in snooker ball manufacturing significantly impacts their performance on the table. High-quality phenolic resin allows for precise weight distribution, critical in ensuring the balls roll true and respond adequately to spin. A well-manufactured ball should demonstrate consistent response behavior, which is desirable among players. Conversely, poor-quality materials can lead to varying performance levels, which may affect game outcomes. Players need to trust the equipment they are using; thus, quality control from reputable manufacturers is indispensable. Additionally, the hardness of the materials used in the production of snooker balls is crucial. Balls that are too soft may wear out quickly or develop surface imperfections, leading to an erratic playing experience. Conversely, if the material is too hard, it can lead to excessive bounce and less control. Therefore, a delicate balance must be struck in terms of hardness and durability, which is achieved through careful selection and combination of materials. Finally, advancements in material science continue to provide manufacturers with new opportunities to improve ball performance, and testing plays an essential role in this evolution.

Different manufacturers have their own proprietary blends of materials, offering players varied experiences depending on their style of play. For instance, some brands may utilize enhanced composite materials tailored for professional play, promising optimal ball speed and control. These innovations can lead to specialized snooker balls designed for different levels of play, from casual to competitive tournaments. The uniqueness in construction allows players to select balls that suit their individual playing styles, promoting satisfaction and preference. Understanding these materials also fosters a deeper connection for players with their equipment, adding a personal touch to the game. Furthermore, snooker balls require maintenance for long-lasting performance. Players must care for their balls through regular cleaning and proper storage to extend their lifespan. The environment in which the balls are kept also plays a role in their durability. Humidity can affect surface conditions, impacting gameplay significantly. Therefore, understanding the properties of snooker balls can enrich the player’s experience, encouraging them to invest in quality equipment. As the game continues to evolve, the materials used in snooker ball production will undoubtedly follow suit, influencing the design and structures of future balls.

Environmental Considerations

As with many products today, environmental considerations in the manufacturing processes of snooker balls are becoming increasingly important. The production of phenolic resin and other synthetic materials involves the usage of chemicals that may raise environmental concerns. Hence, manufacturers are actively researching more eco-friendly options to create sustainable snooker balls. Several companies are exploring the use of biodegradable alternatives and recycling materials to reduce their environmental footprint while maintaining performance standards. Additionally, certifications for environmentally friendly practices can enhance a brand’s reputation among environmentally-conscious consumers. Notably, integrating sustainability into production does not mean sacrificing quality. There are innovative materials that perform well while being less harmful to the environment. The implementation of renewable energy in manufacturing facilities is another angle manufacturers are exploring to lessen their impact. The push for eco-friendly materials reflects a growing awareness of sustainability among players and manufacturers alike. As the snooker community increasingly values sustainability, manufacturers will be compelled to improve material sourcing, production methods, and waste management practices to align with these evolving expectations. This trend is essential for the longevity of the sport and the planet.

In summary, the materials used in the manufacturing of snooker balls are critical to their performance, durability, and overall quality. Traditional choices such as phenolic resin continue to dominate due to their proven effectiveness and reliability on the table. Yet, the industry is embracing innovation, allowing for newer materials to be explored, enhancing playability and player preference. The intricate manufacturing processes showcase the efforts taken to ensure these balls meet rigorous quality standards, providing both amateur and professional players with a trusted product. Today’s manufacturers strive for a balance between traditional processes and modern technology, yielding outstanding results. Environmental sustainability is becoming an ethical responsibility that manufacturers are beginning to address, opting for environmentally friendly materials without compromising performance. Players also play a significant role in advocating for quality products, influencing manufacturers to research and implement superior materials. As the game of snooker continues to grow, so too will the standards for manufacturing excellence and material advancement. Thus, understanding the materials in your snooker balls not only enriches your enjoyment of the game but also helps you make informed choices about your equipment.

Conclusion

The journey of a snooker ball is an intricate blend of design, material science, and craftsmanship. Understanding the materials used in manufacturing provides insight into the choices players make regarding their equipment. The evolving landscape of materials reflects wider trends in technology and environmental considerations. As consumers, players must remain educated and deliberate in their choices, advocating for quality and sustainability in the products they use. Each snooker game starts with the balls players select, and these choices significantly impact their performance on the table. Consequently, both amateurs and professionals stand to benefit from the advancements in material science, leading to improved game experiences. Innovations in sustainable practices will motivate manufacturers to create a more responsible snooker community where environmental impact is minimized while upholding the integrity of the sport. Ultimately, the emphasis on quality materials in snooker balls reinforces the commitment of manufacturers to delivering the best products possible, allowing players to maximize their enjoyment and success on the table. As we look to the future, the continual evaluation and enhancement of snooker ball materials will undoubtedly shape how the sport is played.